GEAR RACKS CAPABILITIES & SERVICES

Your Reliable Custom Gear Rack Manufacturing Partner

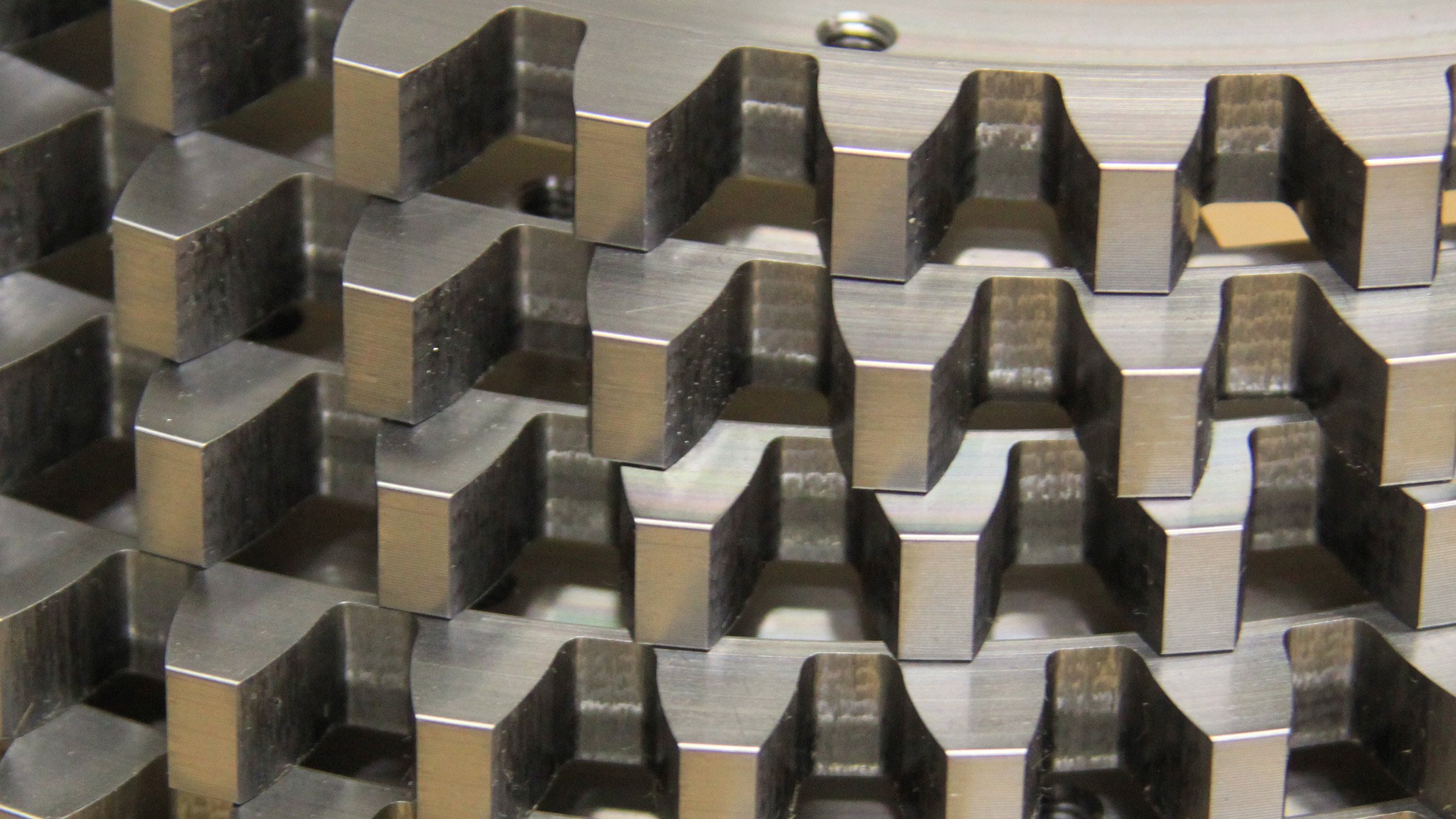

At Avers, our passion is crafting precision-engineered gear racks, the hidden heroes behind efficient machinery. We take pride in our craftsmanship that keeps the world moving smoothly.

Our team has years of experience with gear cutting, gear racks, and heat treatment processes to deliver exceptional accuracy, surface finish, and durability that exceed the most stringent industry standards.

Our Capabilities

Custom Precision Gear Rack Manufacturing.

Proficient in working with a wide variety of materials, from standard carbon /alloy steels and non-ferritic materials like plastics and aluminum to advanced super alloys and exotic stainless steels.

High-precision machining capabilities to achieve tight tolerances and surface finishes through CNC turning, milling, and grinding.

Heat treatment services, including hardening, carburizing, flame, nitride, or induction hardening

A range of surface finishing options, including black oxide, zinc plating, anodizing, and phosphate coatings, improve corrosion resistance and aesthetic appeal.

Capabilities to perform secondary operations, including drilling, tapping, and grinding to provide ready-to-use components.

Advanced CAD/CAM software and 3D modeling for precise design and manufacturing.

Our Schiller Park location is QMS Certified to ISO9001:2015

All gears are manufactured and shipped from Chicago for national distribution.

Flexibility and excellence, irrespective of the production volume.

Leading the Industry: Our Recent Gear Rack Projects

OUR COMMITMENT

With Avers, you’ll gain more than a service provider. We’re your dedicated partner, focused on innovation and technical expertise, to help you achieve your operational goals.

AVER’S CAPABILITIES

By leveraging in-house production engineering capabilities and advanced, automated equipment, we deliver quality components that meet your precise requirements.

GEAR RACKS

We specialize in efficiently manufacturing custom gear racks for multiple applications, with the ability to produce various sizes, pitches, and materials based on your exact specifications.

GEARS

With 30+ years of expertise in gear manufacturing, we have mastered machining, finishing, and reverse engineering of small and medium custom gears.

CNC MACHINING

Combining high-tech equipment and skilled machinists, we have the expertise to create high-precision parts with strict tolerances, exceptional surface finishes, and detailed intricacies at competitive prices.