QUALITY

Where Quality and Precision Meet Commitment

At Avers, we combine the extensive experience of a seasoned company with the innovation and enthusiasm of a start-up. We use advanced equipment and state-of-the-art technology to produce the highest-quality components to meet your specifications.

Our Schiller Park location is ISO 9001:2015 and our Woodstock location is AS 9100D including ISO 9001:2015 QMS Certified underscore our commitment to exceptional quality. We are also ITAR compliant at both facilities, adhering to international defense trade regulations that require us to maintain the highest standards of responsibility and accountability.

Custom Gear Solutions to Meet Your Unique Needs

We manufacture gears in various sizes, pitches, and materials for diverse industries, including aerospace, OEM, food processing, and more. Leveraging high-tech equipment and the expertise of our machinists, we deliver high-precision parts with strict tolerances and exceptional surface finishes at competitive prices.

Quality Standards

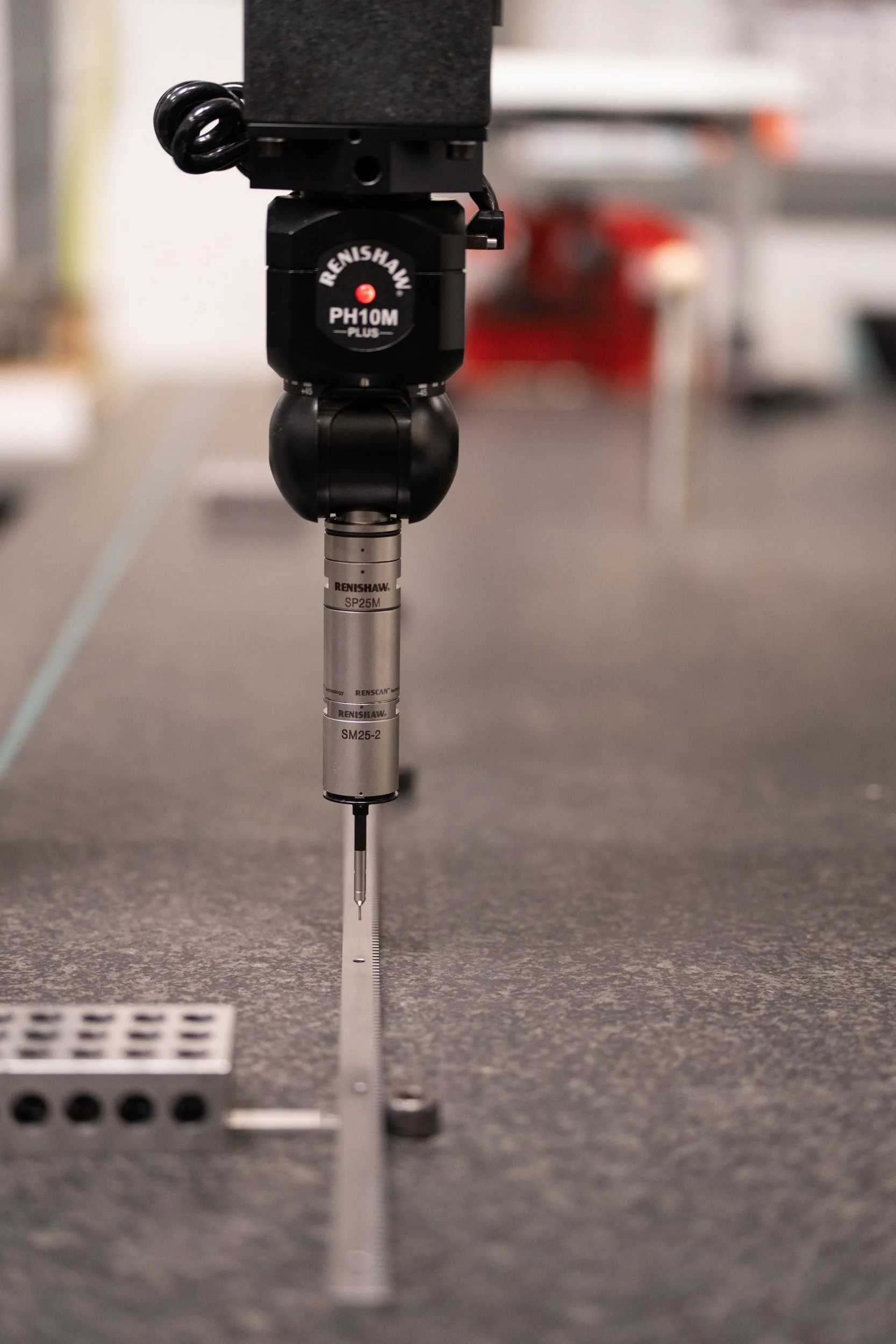

Utilization of advanced CNC inspection machinery to ensure quality products are consistently produced

Regular calibration and maintenance of equipment to ensure consistent accuracy

Comprehensive testing protocols to verify gear accuracy for best performance

Adherence to industry standards and certifications for quality assurance

Continuous improvement initiatives to enhance manufacturing processes

Ensure precision by analyzing pitch, runout, lead, and profile errors to 10 millionths of an inch

Our advanced gear manufacturing processes confirm that every component meets the highest standards of precision and performance.

Custom Gear Racks that Exceed Your Quality Expectations

Our gear rack capabilities cater to applications with straight and helical tooth options. We manufacture gear racks from .500 DP to 120 DP for straight teeth and 3 DP to 48 DP for helical teeth, crafted from steel, bronze, stainless steel, tool steels, plastics, and aluminum. With our years of experience and heat treatment processes, we deliver exceptional accuracy, surface finish, and durability that exceed the most stringent industry standards.

Quality Standards

Precision-engineered gear racks with meticulous attention to tooth accuracy for flawless performance

Comprehensive incoming material inspections to verify compliance with specifications

In-process inspections using precision measurement tools to ensure dimensional accuracy and consistency

Non-destructive testing methods, including ultrasonic and magnetic particle inspection, to detect internal and surface defects

Final quality audits and functional testing to confirm all finished gear racks meet performance and durability requirements before shipment

We manufacture various types of racks, including custom, stock, spur, helical, worm and worm gears, turned products, and milled products to meet your exacting needs.

Precision CNC Manufacturing Dedicated to Delivering Quality

Using high-precision CNC machining, we specialize in aerospace, automation, OEM niche parts, and other machined products for the energy, agricultural, mining, chemical processing, and hydraulic markets. We use advanced multi-axis CNC programming for complex part geometries and precision machining to ensure exceptional accuracy and surface finishes.

Quality Standards

Precision-matched sets and serialization with material lot control, guaranteeing exceptional accuracy and traceability when needed

In-process inspections using precision measurement tools to ensure dimensional accuracy and consistency

Non-destructive testing methods, such as ultrasonic and magnetic particle inspection, to detect internal and surface defects

Detailed documentation of each production step, including inspection results and corrective actions, to ensure traceability and accountability

We also provide value-added capabilities upon request, including the manufacture and light assembly of components with bearings, bushings, and helical insert installation.

Precision Meet Commitment: Our Recent Quality Projects

Experience the Avers Difference

Quality is the foundation of everything we do. We pride ourselves on delivering precision components that meet the stringent quality standards of top-tier clients worldwide. Partner with us today to achieve unmatched precision and outstanding quality.

Avers utilizes state of the art measuring equipment in our quality inspection laboratories. We use equipment from brands such as Zeiss, Wenzel, Mitutoyo, Kapp Niles, Penta Gear and Keyence to name a few. We are ready for any task and we can use any of our four CMMs, analytical gear inspection centers, CNC vision systems and Atomic Absorption Spectrometers. We inspect your parts at every step of manufacturing with 1st piece, in-process and final inspection

AVER’S CAPABILITIES

By leveraging in-house production engineering capabilities and advanced, automated equipment, we deliver quality components that meet your precise requirements.

GEAR RACKS

We specialize in efficiently manufacturing custom gear racks for multiple applications, with the ability to produce various sizes, pitches, and materials based on your exact specifications.

GEARS

With 30+ years of expertise in gear manufacturing, we have mastered machining, finishing, and reverse engineering of small and medium custom gears.

CNC MACHINING

Combining high-tech equipment and skilled machinists, we have the expertise to create high-precision parts with strict tolerances, exceptional surface finishes, and detailed intricacies at competitive prices.